THE REALITY OF LIVING IN GASLAND, PENNSYLVANIA

"..Almost six months later, the other well we found is flaring. This well is only about a quarter mile from the house I spent the last ten years in, and where my mom and her husband still live. If a well nearly a mile away was able to make more noise than my TV and my air conditioner, I can only imagine the kind of noise my poor mother is dealing with right now."

This blog, focusing on drilling in central West Virginia, seeks to reveal the unpleasant truths about Hydraulic Fracturing. aka Fracking. According to a recent study, conducted by the Environmental Working Group (EWG), just one drilling site deploys harmful chemicals sufficient "to contaminate more than 100 billion gallons of drinking water to unsafe levels ... more than 10 times as much water as the entire state of New York uses in a single day."

Monday, November 28, 2011

FARM ANIMALS ARE GETTING SICK AND DYING.. PEOPLE WILL BE NEXT - BAN FRACKING EVERYWHERE UNTIL IT CAN BE SAFELY REGULATED!

More than 35% of North Dakota’s natural gas production is being flared/not marketed, due to insufficient pipeline and processing capacity, the US Energy Information Agency reports.”The percentage of flared gas in North Dakota is considerably higher than the national average; in 2009, less than 1% of natural gas produced in the United States was vented or flared. No doubt, many of the effects on animals recorded in this video are from gas flare byproducts, as well as from open waste fluid pits and condensate tanks. This breaks my heart.

Saturday, November 26, 2011

REAL PEOPLE, REAL LIVES DESTROYED BY HYDRAULIC FRACTURING AND HORIZONTAL DRILLING in PAVILION, WYOMING

Wake up West Virginia! In Pavilion, Wyoming, residents have been told NOT to drink the water as their evidence shows that their water has been contaminated by dangerous chemicals used exclusively in fracking.

Chemicals Being Hauled Into the Big Laurel Gas Well Site, Richwood, Nicholas County, WV

The fact is that IF the same regulations (Safe Air/Safe Water Acts) legislation that applies to the US coal industry were applied to the hydraulic fracturing/horizontal drilling industry (it was exempted unfer the "Haliburton Loophole", making it the ONLY industry that can legally inject known toxins directly into sources of drinking water without federal regulation) then this process would be far less economic for the operators, and the massive investment houses would probably drop their interests like a hot potato. The industry denies contamination occurs although it has bought off many thousands of people who have complained of water contamination.

Here is a rancher, Louis Meeks, from Pavilion, Wyoming.. a Vietnam vet, talking on the issue. A video interview is included "..They can get the gas out, but they need to do it right. And we need to protect the people and the water for future generations. They have made such a mess out here they will never clean it up. So now what are we suppose to do for water? I can’t live without good water, Can you?"

VIETNAM VET LOUIS MEEKS OF PAVILION, WYOMING, TALKS ABOUT HOW HYDRAULIC FRACTURING AND HORIZONTAL DRILLING HAS RUINED HIS WATER AND HIS LIFE

Elsewhere, MARCELLUS SHALE FRACTURING IMPACTS HUNTING CLUB - The bubbling flow has attracted generations of folks from Clearfield County and beyond, but staked into the ground now is a homemade sign bearing the warning: "Contaminated Water."

The sign seems out of place. Larry Righi certainly thinks so, even though he had a hand in putting it up months after a torn liner under one or more EOG Resources Marcellus Shale drill cuttings pits allowed leakage that contaminated groundwater feeding the spring almost two years ago.

The sign seems out of place. Larry Righi certainly thinks so, even though he had a hand in putting it up months after a torn liner under one or more EOG Resources Marcellus Shale drill cuttings pits allowed leakage that contaminated groundwater feeding the spring almost two years ago.

Friday, November 25, 2011

HUNTING IS HUNTING AND FRACKING IS FRACKING AND NEVER THE TWAIN SHALL MEET..

STATE GAME LAND 59, Pa. — For those who have ever stalked deer, turkey and bear here in “God’s Country” in north central Pennsylvania, this hunting season is like no other. For one thing, it is louder. The soundtrack of birds chirping, thorns scraping against a hunter’s brush pants and twigs crunching underfoot is now accompanied by the dull roar of compressor stations and the chugging of big trucks up these hills.

READ MORE

Wednesday, November 23, 2011

NATIVE AMERICANS SAY "BAN FRACKING"

Native Americans on Fracking

Please watch and share this inspirational video. Then "Make your decisions on behalf of the seventh generation coming".

ANOTHER EXPLOSION ON THE TENNESSEE GAS PIPELINE - ANOTHER WELD FAILURE?

23rd November 2011 Gas line explodes near Batesville, Mississippi - probable weld failure

(WMC-TV) - Panola County authorities are investigating what caused a natural gas pipeline explosion and fire near Batesville that forced the evacuation of 20 to 30 families.

There were no injuries or fatalities related to Monday's incident. Authorities allowed the fire from the ruptured Tennessee Gas Pipeline line to burn out overnight. The pipeline is located off Mississippi Highway 6 west of the Tallahatchie River and west of Batesville.

Emergency Management Director Daniel Cole said fire departments from across the county were mobilized but were released Monday night as the fire died.

"It is my understanding the line itself did not rupture," Cole said. "It was a leak."

Cole said families were moved to a community center about two miles away from the fire.

"Twenty minutes into that evacuation the gas found an ignition source and did ignite, and at that point in the time we deployed three fire departments to standby to protect structures that might have been in danger," he said.

Tennessee Gas personnel shut off the supply of gas feeding through the pipeline, allowing the excess gas to burn off.

Tuesday, local officials re-opened State Highway 6, and Macedonia Road, which had to be closed.

Then we have this from a week ago:

16th November 2011 Gas line explodes near Glouster, Ohio, destroys 3 Homes, Barn- CONFIRMED WELD FAILURE

10th Feb 2011, Hanover County, Ohio, a Tennessee Gas pipeline exploded. CONFIRMED WELD FAILURE

Incidentally, after the explosion in the same area on 10th Feb (see pic below) Tennessee Gas were ordered to carry out repairs at a number of sites as follows:

On March 11, 2011, PHMSA issued a Notice of Proposed Safety Order (Notice)1 to Tennessee Gas, alleging that certain segments of Respondent's natural gas pipeline system designated as the Line 200 Pipeline System had conditions that, without corrective measures, would pose a pipeline integrity risk to public safety, property, or the environment. Specifically, the Notice alleged that the conditions causing a February 10, 2011 failure on Line 200-4 in mainline valve section 214 (Line Section 214-4), approximately 2.5 miles southeast ofthe town of Hanoverton, Ohio, and the March 1, 2011 failure on Line 200-1 in mainline valve section 209 (Line Section 209-1), approximately 0.5 miles downstream of the Cambridge Compressor Station 209, demonstrated the presence of integrity risks on those segments of Lines 200-1, 200-2, 200-3, and 200-4 running from Compressor Station 200 to Compressor Station 219, including the Pittsburg Spur (Affected Segments). PHMSA and Tennessee Gas entered into a Consent Agreement that was incorporated by reference into a Consent Order issued on March 31, 2011.2

At the time of the November explosion this work had not been completed.

And remember, it's not just the immediate impact of an explosion. These pipelines are loaded with PCB's. When PCB's burn they form Dioxins (remember Bhopal?) PCBs are known to cause cancer, birth defects and reproductive harm. PCBs also damage and disrupts hormone activity especially in women, children and older members of the population.

Columbia Gas Transmission - Superfund site - PCB's and other Contaminants

FYI, most of Columbia Gas Transmission's property in West Virginia constitutes a Superfund site due to high levels of PCB's, Benzene, Toluene, and Xylene and Mercury in adition to various Polycyclic Aromatic Hydrocarbons. They were ordered to clean up in 1994, and are still doing it. So much for "Clean Natural Gas".

"Prior to 1976, polychlorinated biphenyls (PCBs) were widely used by industry in lubricating oils for electrical equipment and hydraulic systems because of their exceptional heat transfer characteristics. Portions of Columbia's pipeline, including natural gas compressors, have become contaminated with PCBs. Columbia maintains that these PCBs have been introduced into its pipeline system as a result of interconnections with natural gas transmission pipelines of other companies that used lubricating oil containing PCBS, and that Columbia did not use PCB lubricating oils in its natural gas compressors.

As a result of normal pressure and temperature changes within Columbia's pipeline, constituents contained in natural gas can condense into a liquid form within the pipeline. This liquid, or condensate, may contain, among other things, benzene, toluene, and xylene. The condensate may additionally contain PCB-contaminated lubricants that have entered the pipeline. Condensates must be removed to avoid damage to the gas compressors. Condensate is removed from Columbia's pipeline through numerous liquid removal points at various locations along the pipeline system. The most common type of liquid removal point consists of a liquid trap attached to the pipeline and a length of small-diameter pipe with an above-ground valve, Columbia's pipeline includes approximately 15,000 liquid removal points where condensates are or were removed from the pipeline. Condensate, removed from Columbia's pipeline was disposed by Columbia onto the ground at liquid removal points, stored in aboveground and underground storage tanks, and/or disposed of in trash disposal and burn areas at various locations along the pipeline system. As a result of this practice soils along the pipeline, in the vicinity of the storage tanks, and in the trash disposal and burn areas have become contaminated with, among other things, PCBS, benzene, toluene, and xylene.

There are approximately 3,000 locations along Columbia's pipeline where mercury-filled metering devices are used to measure pipeline flow and pressure. Routine maintenance activities performed on these devices has resulted in drips and spills of mercury from a number of these devices onto the ground in the vicinity of these devices. Soil in the vicinity of these instruments has become contaminated with mercury"

Tuesday, November 22, 2011

ILLEGAL WELL FLARING, NOTICE OF VIOLATION - RICHWOOD WEST VIRGINIA

This is the view of the Illegal gas flare at the Rupert well site up above to the west of Richwood, Nicholas County, west Virginia. A temporary gas flare is only allowed to flare for 30 days in one year. As of yesterday, the company, BRC Operating Company, LLC, a "daughter" company of Bluescape Resources Company, LLC, had been flaring continuously for 86 days. That means that a theoretical fine of $560,000 could be levied by the state of West Virginia...

The following is the text of the notice of violation that was sent to Bluescape on October 26th, 2011, two weeks after inspectors visited the site on Oct. 12th. The actions were initiated by members of STUN (STand Up Now), a group of concerned local individuals located in Richwood.

Division of Air Quality

www.dep.wv.gov

Phone: (304) 926-0475 Fax: (304) 926-0479

October 26, 2011

CERTIFIED MAIL

Article # 91 710821333936 15552457

Bluescape Resources Company LLC c/o Mr. Don Campo, Chief Operations Officer 200 Crescent Court Suite 200 Dallas, TX 75201

RE: NOTICE OF VIOLATION (NOV) MWV Rupert Well Flare Site

Dear Mr. Campo:

On October 12, 2011, personnel from the Division of Air Quality (DAQ) conducted an inspection of the Bluescape Resources Company LLC, MWV Rupert Well Flare Site (Company) located nearFenwick,

WV.

The DAQ has determined the natural gas well flare located at the MWV Rupert Well Flare Site does not meet the requirements as a temporary flare stack under 45CSR6, specifically, Section 6.1.

This determination is based on the flare stack operating continuously since August 28, 2011, which exceeds the maximum number of cumulative days of operation allowed within a twelve (12) consecutive month period in

accordance with Section 6.1 of 45CSR6. Therefore, the Company has violated 45CSR6, in particular, Section 6.1 for not obtaining a permit in accordance with the provisions of W.Va. Code §22-5-1 et seq. and 45CSR13 (Rule 13).

You should be aware that for each violation your Company may be subject to civil and/orcriminal penalties and further action or remedies as provided by West Virginia Code §§ 22-5-6, which may include imposition of a

civil penalty of up to ten thousand ($10,000) dollars per day for each violation.

A written response to this Notice of Violation is required from your Company within ten (10) days after receipt. The following information must be in your response to the Notice of Violation:

(1) A detailed explanation of the cause(s) of the condition(s) leading to the cited violation or a description of the action(s) being taken or to be taken to ascertain the cause(s) for noncompliance.

(2) A statement of how long the condition(s) has existed.

(3) A detailed explanation of the remedial measures that have been taken and will be taken to address the causes of noncompliance.

For any remedial measure(s) not yet taken, provide expected date(s) for completion. If all remedial measures have been completed, provide the date that the Company believes that compliance with airquality requirements

was achieved.

Please be aware that any person who knowingly misrepresents any material fact in an application, record, report, plan, or other document filed or required to be maintained under the provisions of West Virginia Code

22-5-1, et seq., or any rules promulgated thereunder, is guilty of a misdemeanor and, upon conviction, shall be fined not more than twenty-five thousand ($25,000)dollars or imprisoned in the county jail not more than six months or

both fined and imprisoned.

Furthermore, any person who knowingly violates any provision of West Virginia Code22-51, etseq., any permit or any rule or order issued pursuant to that article is guilty of a misdemeanor and, upon conviction, shall be fined not more than twenty-five thousand ($25,000.00)

dollars for each day of such violation or imprisoned in the county jail not more than one year or both fined and imprisoned.

Further, please note that for purpose of the foregoing, violations on separate days are separate offenses.

The Division looks forward to your timely written response to this Notice of Violation.

---------------------------------------------------------------------------------------------------------------

Here is Bluescape's response:

November 8, 2011

John Benedict, Director, Division of Air QualityWV Department of Environmental Protection

601 5th Street

Charleston, West Virginia 25304

Notice of Violation

The Noticeof Violation states: The DAQ has determined the natural gas well flare located at the MWV Rupert Well Flare Site does not meet the requirements as a temporary flare stack under 45CSR6, specifically, Section 6.1. This determination is based on the flare stack operating continuously since August 28, 2011, which exceeds the maximum number of cumulative days of operation allowed within a twelve (12) consecutive month period in accordance with Section 6.1 of 45 CSR6.Therefore, the Company has violated 45CSR6, in particular, Section 6.1 for not obtaining a permit in accordance with the provisions of W. Va. Code §22-5-1 et seq. and 45CSR13 (Rule 13).The NOV requires BRC to make a written response within ten (10) days after receipt.

The MWV Rupert Well Flare Site (the "Site") consists of a series of three natural gas wells that flow to a single flare stack. The Site is located in a remote part of Nicholas County, and to date no natural gas pipelines have been installed on or in the vicinity of the Site. BRC installed the three wells on the Site to determine whether the acreage that it has leased from MeadWestvaco Corp. are economically viable. If the wells, and

others planned in the surrounding area of Nicholas County, are proven to have sufficient productivity to be economically viable, then BRC will work to install a natural gas pipeline to allow the production from these reserves to reach a commercial market. The Site is the first location in Nicholas County to test the viability of the natural gas reserves in the area. Because no pipeline exists in the area, BRC must flare the natural gas that is produced by the three wells at the Site.(2) A statement of how long the conditionts) has existed.

The first of the three wells at the Site began producing methane around noon on August 29, 2011. The second and third wells began production on August 31, 2011, and September 3, 2011, respectively. Initial production was very low, and has increased to the current production levels over the past two months.

(3) A detailed explanation of the remedial measures that have been taken and will be taken to address the causes of non compliance. For any remedial measure(s) not yet taken, provide expected date(s) for completion. If all remedial measures have been completed, provide the date that the Company believes that compliance with air quality requirements was achieved.

BRC is preparing a permit application pursuant to 45 CSR 13, which will be submitted by November 15, 2011. The application is based upon standard AP-42 emission factors for industrial flares and natural gas combustion. BRC believes that these emission factors are likely to grossly overestimate the emissions of CO and NOx from the flare, as the gas being burned in the flare is almost entirely methane and therefore likely to burn cleanly. If more appropriate emission factors were available, it is possible that BRC would not require a permit pursuant to 45 CSR 13 for the flare. In the absence of appropriate emission factors, BRC is submitting the permit application for the emissions from the

flare.Executive VP + Chief Operating Officer

--------------------------------------------------------------------------------------------------------------

Still awaiting the next exciting instalment.. and as far as Bluescape is concerned, the radar's still running guys!

FRACKING IS A PONZI SCHEME!

The truth is starting to come to light.. and the sooner the investors who have poured untold billions into the Marcellus Shale play know this, the quicker that house of cards will come tumbling down.

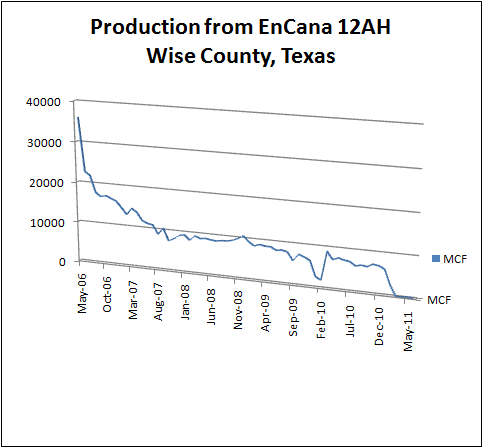

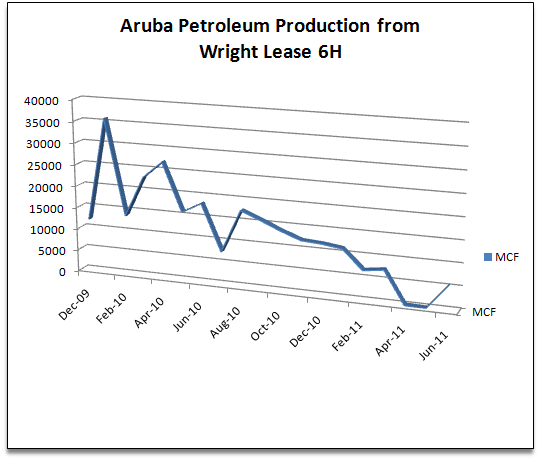

Unconventional gas drilling IS a Ponzi scheme. Production from a well falls off so quickly that the next well has to be ready to go as soon as the first one is drilled.. then the next well.. then the next well.. leaving environmental chaos in its wake, and the industry KNOWS this! There are hundreds of industry e-mails and internal documents and an analysis of data from thousands of wells. There is NO BASIS for their claim that these wells last 20 or 30 years! Maybe they will struggle for two or three years.. without expensive nitrolifting and re-drilling, a well stops producing in as little as 10 months.. hence the need to constantly drill new ones.

Leaked Documents: Industry Privately Skeptical of Shale Gas

Here is a graph of shale gas production over time for a gas well in the Barnett Shale play:

The picture is similar for every well. Here's another:

The temporary upward "blips" were achieved by bringing in nitro lift units and installing huge compressors.. this is a very expensive process that enables the well to "squeeze" a little harder. Still, nowhere near the initial surge.

an analyst from PNC Wealth Management, an investment company, wrote to a contractor in a February e-mail:

“Money is pouring in” from investors even though shale gas is “inherently unprofitable,” “Reminds you of dot-coms.”

Good! The sooner the investors have their eyes opened then the quicker the "bust"!

Unconventional gas drilling IS a Ponzi scheme. Production from a well falls off so quickly that the next well has to be ready to go as soon as the first one is drilled.. then the next well.. then the next well.. leaving environmental chaos in its wake, and the industry KNOWS this! There are hundreds of industry e-mails and internal documents and an analysis of data from thousands of wells. There is NO BASIS for their claim that these wells last 20 or 30 years! Maybe they will struggle for two or three years.. without expensive nitrolifting and re-drilling, a well stops producing in as little as 10 months.. hence the need to constantly drill new ones.

Leaked Documents: Industry Privately Skeptical of Shale Gas

Here is a graph of shale gas production over time for a gas well in the Barnett Shale play:

The picture is similar for every well. Here's another:

The temporary upward "blips" were achieved by bringing in nitro lift units and installing huge compressors.. this is a very expensive process that enables the well to "squeeze" a little harder. Still, nowhere near the initial surge.

an analyst from PNC Wealth Management, an investment company, wrote to a contractor in a February e-mail:

“Money is pouring in” from investors even though shale gas is “inherently unprofitable,” “Reminds you of dot-coms.”

Good! The sooner the investors have their eyes opened then the quicker the "bust"!

Subscribe to:

Posts (Atom)